Have you ever wondered how balloons are actually made?

I don't think we need to explain what balloons are here. Balloons come in all sorts of shapes, sizes and colors. Whether for kids or adults, most of us would agree that no party is complete without balloons.

So let’s take a moment to learn more about the fascinating process of making balloons.

How are balloons made?

Before we look at how balloons are made, we first need to know where the rubber comes from.

The Balloon

Photo: Niko Havranek

The balloon as we know it today differs from the earlier balloons in that it is made entirely of rubber. Modern balloons are usually made of latex, a milky substance that comes from the rubber tree and is considered biodegradable . Balloons made of rubber are first pre-vulcanized and then mixed with stabilizers, plasticizers and the like. To create the desired color, a few pigments are added and then production can begin.

The Evolution of the Balloon

Photo: Paolo Monti

The rubber or latex balloon products we use today have had to go through a period of evolution and invention. These developments have been taking place slowly and gradually over the years since Michael Faraday in London first invented them in 1824. Surprisingly, they were made at the time for laboratory use in experiments with various gases.

Where does rubber come from?

Photo: Onepixel

The rubber for balloons comes from the large rubber trees . A truly unique tree. If you scratch a notch in the bark, for example, a white, milky liquid runs out. You could even say that the tree can be "milked".

In order for this milk to become rubber, stabilizers are added so that the rubber does not age and rot so quickly, as well as a so-called vulcanizing agent, which makes the rubber elastic and stretchable.

Photo: Niko Havranek

Color pigments are also added and ensure that the milk takes on a bright color at the end. The whole thing is now called raw rubber mixture . The factory needs huge quantities of this raw rubber mixture. The mixture is kept in several vats in a variety of colors. If necessary, additional color is added using a hose.

And now it finally starts.

The manufacturing process

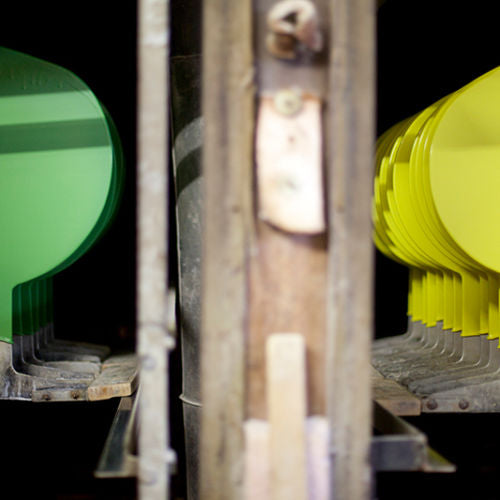

Photo: Niko Havranek

It all starts with a huge machine. There are many cone-shaped templates hanging on it. These shapes now have a little journey ahead of them. The basic principle of making a latex balloon is dipping a mold made of stainless steel, aluminum or porcelain into liquid latex. This shape defines the appearance of the balloon.

First, the molds are dipped in salt water. They resurface evenly covered with salt water.

Now we move on to the colored raw rubber mixture. Here, too, the molds are slowly and evenly dipped into the mixture and pulled through the basin. The salt water ensures that the rubber mixture adheres well without sticking. At the other end, the molds resurface and are covered in a colored raw rubber film.

The journey continues.

Photo: Niko Havranek

Photo: Niko Havranek

At the next station, a brush scrubs around the neck of the molds and rolls down the upper edge a little. A good two centimeters are rolled up. This is called "edging" and creates a nice rolled edge. The rolled edge is there to prevent air from blowing past the side later. After a few seconds, the latex is removed from the mold with a thin layer of latex.

Pretty clever!

To turn the raw rubber into rubber, the balloons are placed in the oven. The balloons are vulcanized in the oven with hot air. This is where raw rubber, which can tear, is finally transformed into rubber that is elastic. The molds are therefore heated before being inserted into the latex for a few seconds at a temperature between 38°C and 93°C to prevent air bubbles from being trapped. Coagulants cause the latex to adhere to a mold and form a thin layer.

Photo: Niko Havranek

Now the balloons just have to be removed from the mold. First, the balloons are inflated with compressed air. It inflates the balloon from the side and blows it down. Then rotating rollers pull the balloon down from the mold.

One floor down, the balloons land in a basket or chest. And now the balloons are ready.

How are the balloons printed?

But we still haven't figured out how the balloons get their print, have we? If you want the balloon printed, there are special processes. It's important that a colored motif is pressed firmly onto the balloon so that it is nice and even. For printing, balloons are inflated to a certain size. After the balloons have dried, they are pulled through a machine that prints the motif on using the desired colors.

The finishing touches

Photo: Niko Havranek

Now the balloon is almost finished. The balloons are still a bit slippery, however, because they are removed from the mold with a soap solution. This remaining soap must therefore be washed off. To do this, the balloons are dipped in a large soap bath and gently rubbed with a brush.

The balloons then go into the drying chamber where they get a round of hot air. They then end up in large containers where they are carefully counted before being hermetically packaged.

Summary

Now you know how balloons are made: from "milking" the rubber tree to dipping them in colored rubber, rolling the top edge and baking the balloon. And how do the balloons come out of the mold? With a little compressed air. Maybe the next time you blow it up you'll think about the fascinating story behind this little balloon.

Check out our huge selection of latex and foil balloons in our online shop !